Prefabricated Buildings in India – REPL

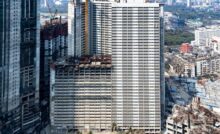

New Delhi, Nov 21, 2014 – Prefabricated design has come to be known as a fast, green, and cost-efficient way to create buildings. Although this technique has most prominently been used with small residential structures, it’s now taken a turn towards greater, larger projects. Prefabricated design has been around since at least the 1940’s, but has lately seen resurgence in popularity. By assembling off-site, prefab gives homebuyers attractive alternatives to the standard residential developments that have become commonplace. While prefabricated homes are not without their disadvantages, they are an interesting component of the post-housing bubble residential market.

Over the years, architects have pushed prefab into some startling new directions, designing futuristic pod houses and modernist boxes on stilts that can be packed up and moved to a new site whenever the owner wants. To see them is to be dazzled by their sheer inventiveness.

Material advances in the prefabrication housing market have also helped to mitigate material failures. The use of fly ash in concrete increases its workability and improves thermal performance. Material such as fly ash is captured from the coal burning process that generate electricity and then reused to manufacture more durable and stable building materials in a factory environment.

In India there are 6 distinct climate zones ranging from cold and dry to warm and wet. Therefore, India’s architecture is varied in its use of materials, style of construction and cultural difference that cannot be generalized. Prefabrication in a technology transfer mode struggles take into consideration these vernacular differences.

Prefabrication has some advantages: It is typically cheaper to build than on-site construction and it usually takes less time for construction to be complete. Pre-fab structures are very sustainable

because they reduce the amount of waste produced.

However, prefabrication can have its disadvantages- First of all, there can be more risk with the prefabrication technique than in traditional construction: since the majority of the large building components are constructed off-site, there is a great amount of trust given to the manufacturer to produce precisely what is needed. One single error can eventually put the entire building in danger.

Workers are constructing under an intense time limit in order to complete the task quickly, and this can lead to a higher potential of mistakes being made compared to traditional on-site methods not

typically associated with rapid completion times.

Conclusion being, pre-fabrication has plenty of advantages –

particularly if you live by the adage that “time is money” since it promises lower construction cost, a quicker schedule, and less waste. However, when human safety is concerned, quality cannot be sacrificed for efficiency (not to mention that, if, in the name of safety, any changes do need to be made to prefabricated materials once they arrive on site, it is an expensive and time-consuming fix). As pre-fabrication continues to boom, we must take the utmost care to ensure its quality – just as we do with traditional construction – or else all the time and money gained will result in a very real, human cost. CCI Newswire

Recent Posts

Housing.com Elevates Buyer-Seller Interaction with ‘Housing Chat’, Boosting Engagement 40X

Approximately 10% of Housing.com users actively utilise the chat functionality New Delhi, April 24, 2025:…

Max Estates takes over Delhi One project in Noida,under the aegis of IBC, adding sales potentialofINR 2,000 Crore and Annuity Rental of INR 120 Crore

Relief to homebuyers as Max Estates takes over ‘Boulevard Projects Private Limited (BPPL)’ to revive…

Mysuru Real Estate Boom: G Square Alchemy Sold 230 Units for 150 Cr in Record Breaking 56 Hours

~ G Square Launches Phase 2 of Alchemy in Mysuru ~ Mysuru, April 24,…

Economic Growth, Urban Expansion, and rising middle class incomes spurring demand for residential real estate

By Anjana Sastri, Director, Marketing, Sterling Developers The outlook for India's housing sector continues to…

Building Success, Delivering Value: How Great Value Realty is Reshaping Indian Real Estate

PAN India, April 23, 2025: Great Value Realty, a premier Delhi-based real estate brand, has…

Mumbai’s Western Suburbs Surge Ahead: Affordable Luxury, Wellness, and Connectivity Drive Housing Demand

41% of 2024 Project Launches Now Concentrated in Suburban Hotspots New Delhi, April 23, 2025:…